Polymer Characterization

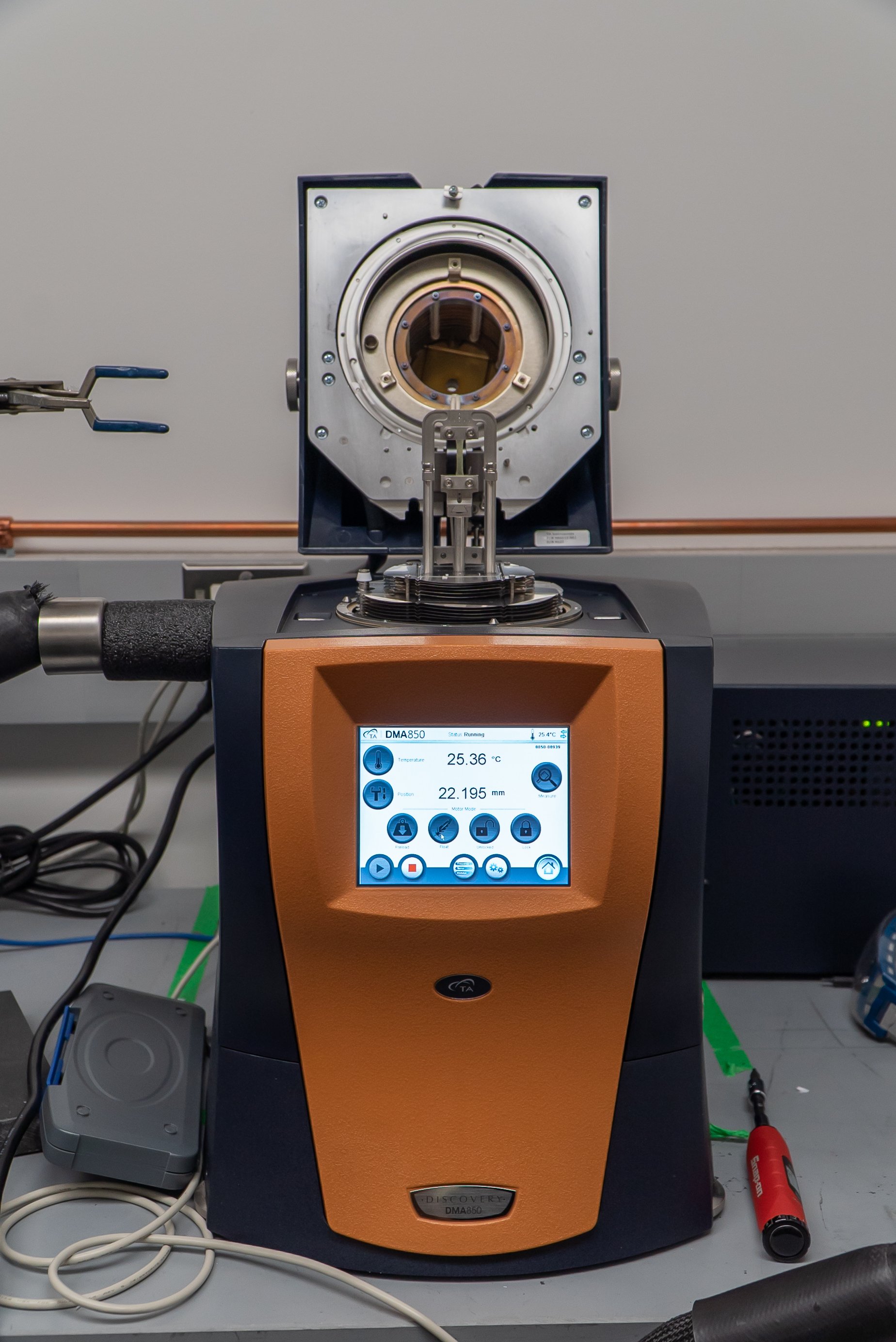

The DMA 850 can be equipped with tension, three points bending, and compression clamp. With different clamps, it can provide various kinds of mechanical property tests to materials. The motor of DMA 850 can deliver continuous forces from 0.1 mN to 18 N with a force resolution of 0.01 mN and a strain resolution of 0.1 nm. When sinusoidal stress is applied, the frequency can be controlled between 0.001 to 200 Hz. The furnace of the DMA 850 can heat up the material to 600 °C, and with liquid nitrogen attached, the material can be cooled to -160 °C. The software of the instrument is TRIOS from TA instrument.

Dynamic Mechanical Analyzer (DMA)

Mechanical testing under uniaxial tension or compression is carried out using a Shimadzu Autograph AGS-50kN (346-58657-02) universal testing machine equipped with a 1kN or 10kN (346-55939-11) load cell. The frame can extend up to 1460 mm at a rate from 0.001 – 1000 mm/min. 1kN samples can be gripped using a pneumatic flat grip (346-52348-01) with either a rubber or steel grip face with a maximum clamp pressure 1000 N. Large samples can be gripped using a pneumatic wedge grip (346-52798-01) with a maximum grip strength of 50 kN. Compression tests can also be carried out using 50 mm diameter compression plates (343-08224-29) with either load cell.

Universal Testing Machine (UTS)

The Discovery Hybrid Rheometer (DHR) 20 from TA Instruments (serial # 5343-0845) is used to study the viscoelastic behavior of different materials in response to applied force. This rheometer utilizes a magnetic thrust bearing to reduce friction and facilitate accurate measurement of low torque values. The instrument is run in tandem with the TRIOS software to measure storage & loss moduli. The instrument is able to run experiments at different temperatures with a temperature ramp rate of 20°C/min. The minimum torque for oscillation is 1 nN.m and for steady sheer it is 3nN.m, both have a maximum of 200 mN.m with 0.1 nN.m resolution. The frequency range is 1.0E-7 – 100 Hz. The angular velocity range is 0 – 300 rad/s. The maximum normal force is 50 N with a sensitivity of 0.005 N and resolution of 0.5 mN. Available instrument accessories include the HR x0 Upper Peltier Plate System (part # 534050.901) with HR x0 Stainless Steel 20 mm (part # 534519.941) and 25 mm (part # 534516.941) Upper Peltier UTS Plate Geometries for heating / cooling (-40 – 200 °C temperature range) samples from above, HR x0 DHR Smart Swap™ Lower Peltier Plate Accessory (part # 533210.901) for heating (25 – 200 °C temperature range) samples from below, UV Light Guide Accessory (liquid light guide compatible, part # 546301.901) with swappable quartz (part # 403153.001) and disposable acrylic (part # 403064.901) plates, an Optics Plate Accessory (part # 546800.901), and HR x0 DHR ARES-G2 APS Stainless Steel 8 mm (part # 402625.901) and 20 mm (part # 402491.901) Quick Change Plates for use without the upper heated plate. A TGA Heat Exchanger (for use with all Discovery & Q TGA’s) (part # 953260.901) is used to control the temperature for both upper and lower accessories. To calibrate the instrument, Canon S60 (low-viscosity) and S600 (high-viscosity) oils are used as standards.